Sensors Made Of Carbon Ceramic Composite Materials

Linear piezoresistivity up to high strain levels.

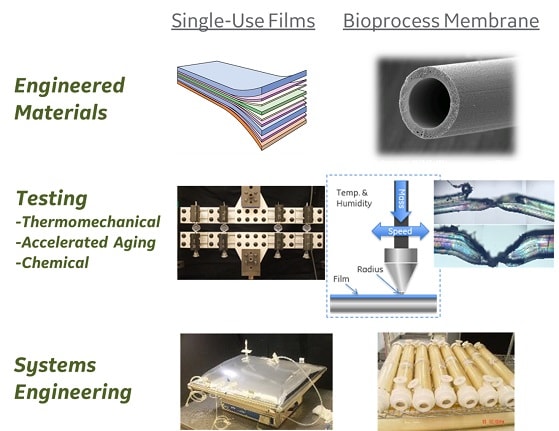

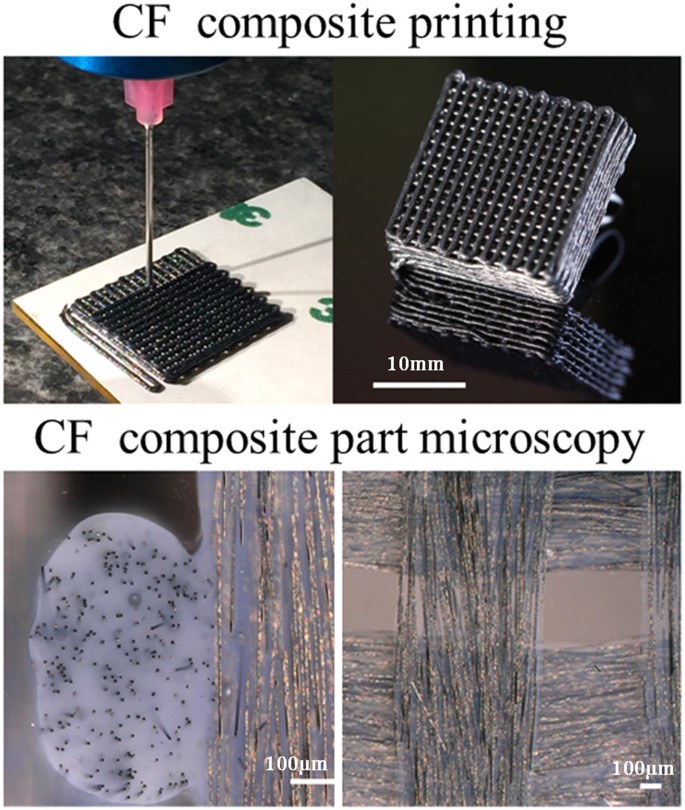

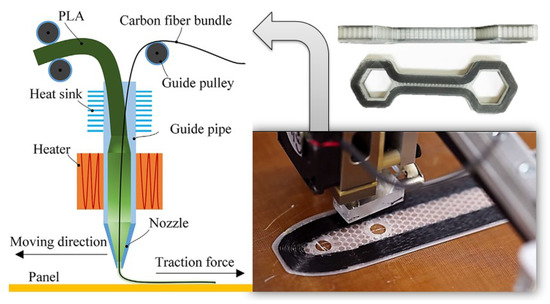

Sensors made of carbon ceramic composite materials. The main matrix component of sic determines the hardness of the composite the effect of carbon fiber is to improve the mechanical strength and fracture toughness of the material and its strength is 5 times higher than steel. Pros wide range of resistance purely resistive highly reliable pulse stability cons wide tolerance physical size limited operating temperature available for only low power ratings. Integral strain measurement method. Carbon ceramic sensor the series scb ccs from the scb family of resistors is based on a carbon ceramic composite construction which adheres to a single resistance verses temperature curve.

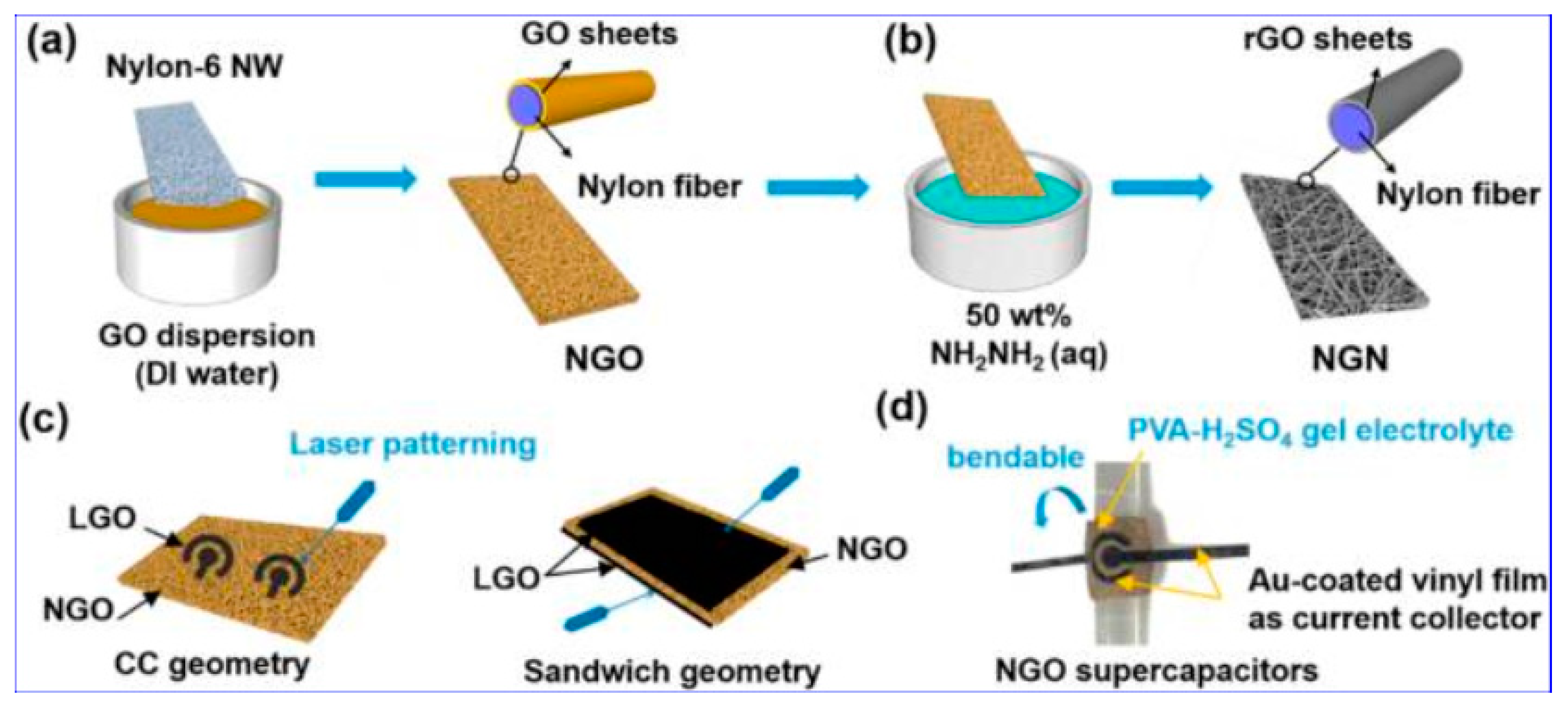

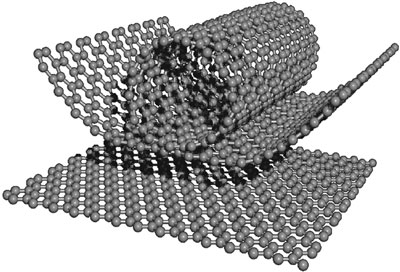

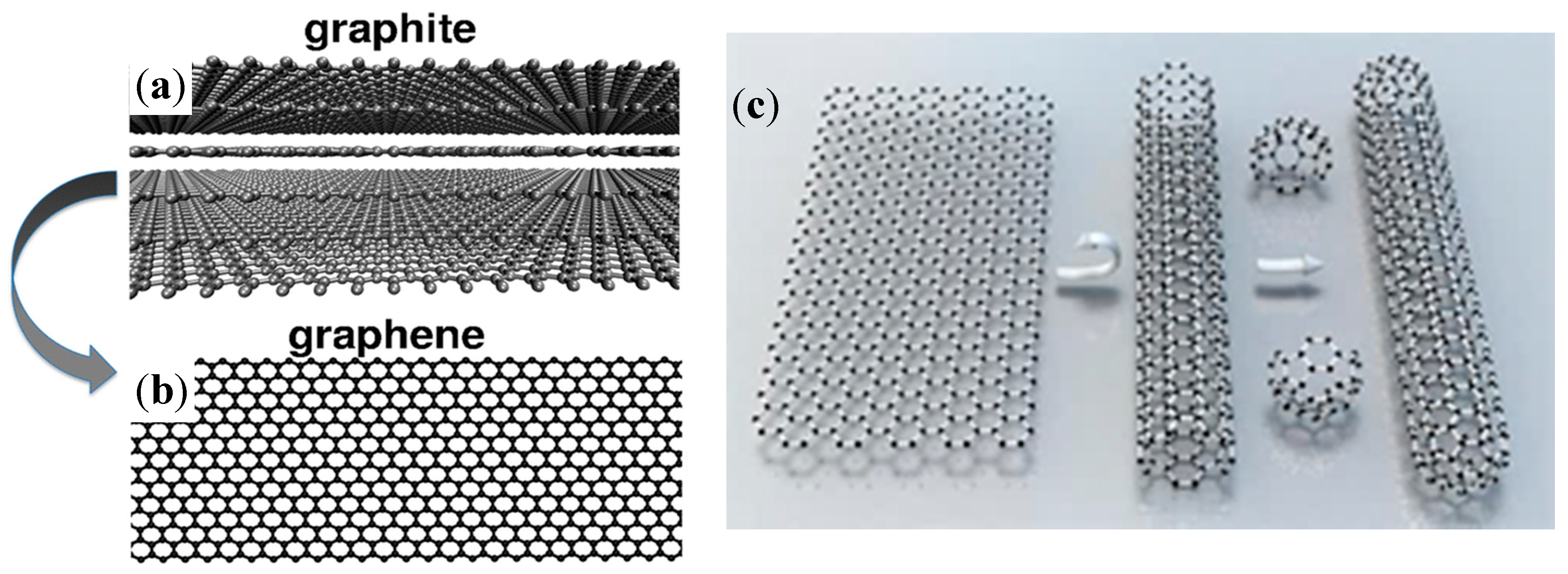

Cnts were deposited on batio 3 substrates using the mpjcvd system. The microballoons may be formed with a second material such as glass carbon or plastic. The output voltages of cnts batio 3 sensors were higher than those of batio 3 sensors. Sigrasic products derive their extraordinary properties from carbon fiber reinforced silicon carbide c sic a composite material that combines carbon fibers within a ceramic matrix to maximize the properties of both materials.

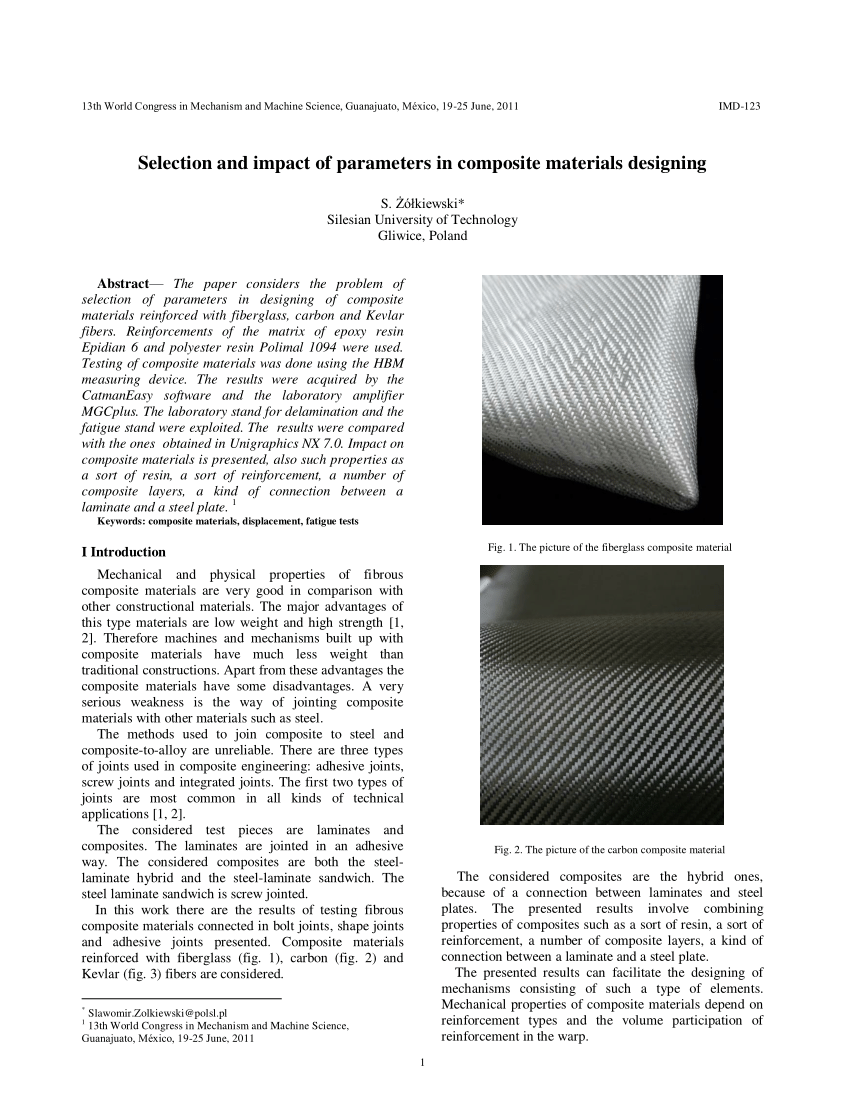

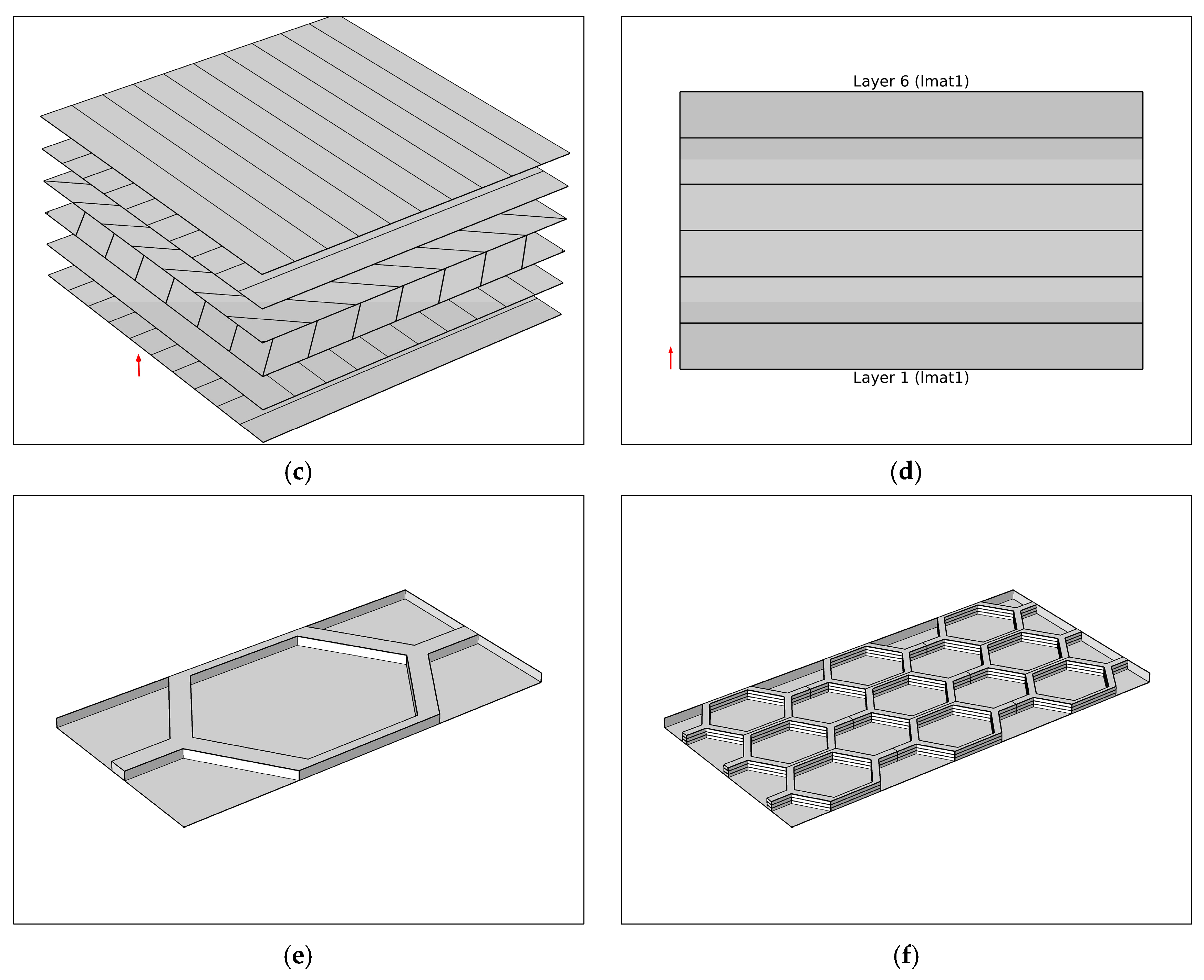

Carbon ceramic composite c sic is a carbon fiber reinforced sic ceramic composite. Many composites such as fiberglass and carbon fiber while containing ceramic materials are not considered to be part of the ceramic family. 4 the earliest ceramics made by humans were pottery objects i e. The benefits of sigrasic are.

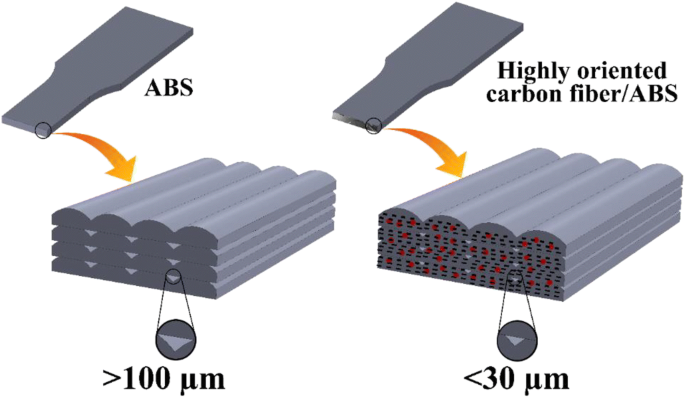

Therefore carbon composition resistors are for common electronics applications where dc or rms voltage remains below 250v and operating. They offer excellent performance and stability characteristics in magnetic field and high dose radiation environments. Carbon composition resistors have the following pros and cons. There are three main aspects which made carbon fibre sensors cfss very interesting to be used for composite materials.

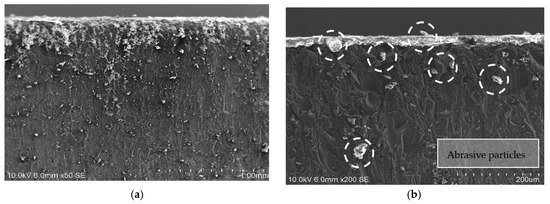

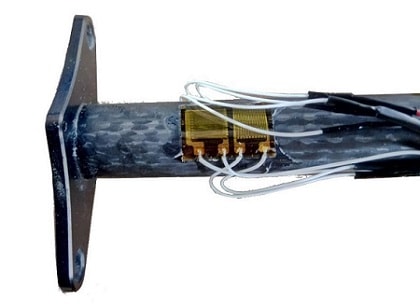

This is often used to great buoyant materials for marine applications such as boat hulls. The composites varied in the size of ceramic grains from 1 23 to 1 58 micrometers and the length and width of graphene. Hard and ductile instead of being brittle. Sensors were made of both carbon ceramic composite materials and ceramics.

The sensitivity of cnts batio 3 sensors were higher than those of batio 3 sensors. Strong lightweight materials made by filling metal plastic or ceramic with hollow spheres known as microballoons. When these values were exceeded cracks spread all over in the material.